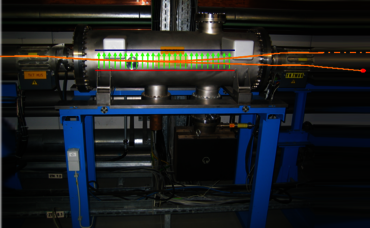

The Chopper is an electrostatic deflection unit in which a well-defined part of the UNILAC beam is guided into the ring accelerator SIS18 by a high-voltage pulse.

First, the beam is deflected from its path by a magnet and, when the chopper is switched off, hits a beam dump after passing through a second magnet. During the high voltage pulse, the beam is influenced by the electric field so that the trajectory of the particles behind the magnets and the chopper corresponds to the original direction.

The beam provided by the UNILAC linear accelerator is too long to be suitable for the SIS18 circular accelerator. The chopper clips the beam that it fills the “phase space” of the SIS18 as ideally as possible. Possible disturbances at the beginning or end of the beam are thus avoided in the SIS18.

Furthermore, the chopper is a safety device for a following injection device (electrostatic injection septum) and devices for beam diagnosis. In the case of a voltage drop, the ion beam is already destroyed at this point in order not to damage the sensitive electrodes in the septum.

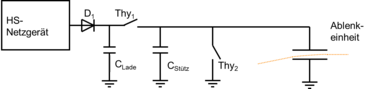

The function is based on the use of high-voltage switching tubes (thyratrons Thy1 and Thy2). These can be switched on very precisely at the desired time.

A high-voltage power supply charges a capacitor (CStore), which is then switched to the deflection unit by Thy1. To stop the pulse, the deflection unit must be discharged via Thy2. The support capacitance (CSupport) stabilizes the voltage at the deflection unit during the pulse flattop.

Depending on the accelerator setting and the type of used ions, voltages from 400V to max. 30 kV for pulse lengths between 1 μs and 400 μs are used.