The “First Wall” for a fusion power plant: GSI/FAIR Materials Research contributes expertise in material development and radiation hardness to the DINERWA project

13.01.2026 |

This news is based on a release by Karlsruhe Institute of Technology KIT

Heat-resistant, radiation-resistant, and industrially manufacturable—these are the essential properties required for the so-called “first wall” of future fusion power plants to withstand the extreme conditions inside a reactor. In the new DINERWA consortium project, funded by the German Federal Ministry for Research, Technology, and Space (BMFTR) with approximately €11 million, researchers from the Karlsruhe Institute of Technology (KIT) are collaborating with partners from science and industry, coordinated by the laser fusion company Focused Energy, to develop novel materials and manufacturing processes. GSI/FAIR is contributing its central expertise in material development and radiation-hardness testing.

Igniting a star on Earth – nuclear fusion is intended to make this possible. Therefore, fusion power plants are considered a major hope for clean and virtually inexhaustible energy production. “One of the greatest technological challenges for future power plants is the ‘first wall. It shields the hot plasma and must endure enormous temperatures and neutron radiation,’” explains Dr. Carsten Bonnekoh from the Institute for Applied Materials (IAM). “In the DINERWA project (“Demonstration of Industrial Manufacturing of a Neutron-Resistant First Wall with Maximized Service Life”), researchers and industry partners are developing suitable materials and manufacturing technologies for this purpose. They also aim to produce test components and examine them under conditions similar to those in a power plant.

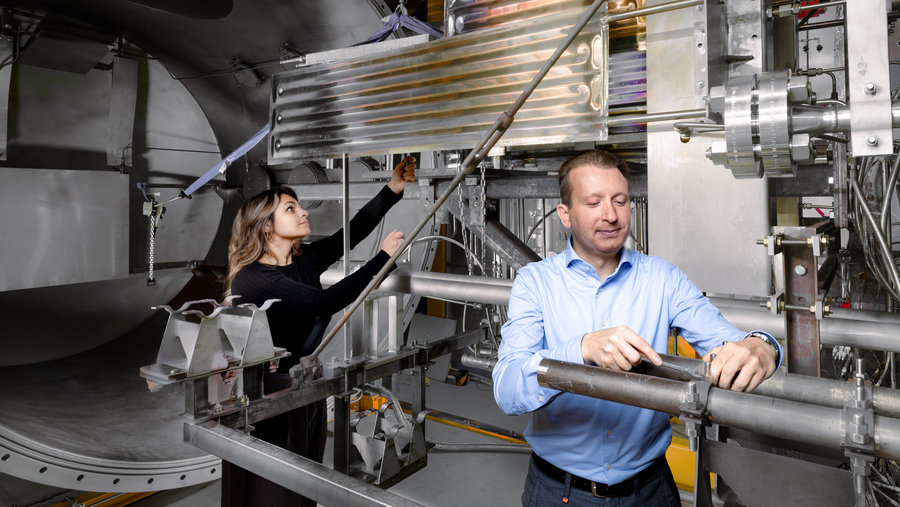

GSI/FAIR’s Material Research Department is playing a key role in the project. The team is contributing substantially both to the development and production of fusion-relevant materials and to the radiation-hardness testing of materials produced by the consortium.

The project focuses on creating durable structural and functional materials that can withstand the high temperatures and intense neutron flux inside the reactor for as long as possible, thereby reducing maintenance costs and downtime for the “first wall.” GSI/FAIR’s expertise in material production and characterization under extreme radiation conditions is a central building block of the project.

In addition to new ODS-based alloys — i.e., oxide dispersion strengthened steels and copper materials — the project partners are also investigating nanostructured tungsten and high-entropy alloys. Complementary manufacturing processes are being developed to reliably assemble these materials into complex modules. “In this way, we want to significantly extend the service life of the ‘first wall,’ ensure its industrial production, and take an important step toward the economic viability of industrial fusion power plants,” says Professor Wolfgang Theobald, lead scientist at laser fusion company Focused Energy and project manager of DINERWA.

The material development is scientifically supported by KIT. Researchers at IAM are developing and characterizing the new ODS steels and copper alloys, while partners scale up the laboratory results for larger production batches and manufacture test components. These components are then tested at KIT’s HELOKA high-heat-flux test facility under conditions that simulate those in a fusion power plant. “We want to demonstrate that these materials not only perform well in the lab but also remain stable under real-world stresses,” says Bonnekoh, who leads the work at KIT. “This will enable us to lay the foundation for actually using these materials, which are still experimental today, in future power-plant components.”

Professor Maria Eugenia Toimil-Molares, head of GSI/FAIR Materials Research, emphasizes: “Our participation aims to ensure that the advanced materials meet the extreme radiation demands of nuclear fusion. Our dedicated ion-irradiation infrastructure and expertise enable us to both produce and test materials under the most extreme conditions. We are pleased to contribute our experience to the DINERWA consortium, which is making a significant contribution to the development of fusion materials for a neutron-resistant ‘first wall’ in future fusion reactors.” (BP)

About DINERWA

The BMFTR is funding the consortium project as part of the “Basic technologies for fusion—On the path to a fusion power plant” program with approximately €11 million. DINERWA exemplifies the close collaboration between research institutions and industry in fusion research and forms the basis for future demonstration plants. In addition to KIT and the coordinating company Focused Energy, industrial partners include CEP Freiberg (producing powder metallurgical copper high-temperature materials, ODS copper), Hermle Maschinenbau GmbH (specializing in additive manufacturing using metal powder deposition), and Zoz GmbH (producing powder metallurgical steels). On the research side, the GSI Helmholtzzentrum für Schwerionenforschung is involved in testing material radiation hardness using ion radiation. The Belgian Nuclear Research Centre in Mol is an associated partner.