Service Areas

PIG ion source service area

In 2012 the PIG ion source service area was set up with new room modules. Inside the ion sources are serviced. Single use wear parts are changed and if required a general maintenance service is done. There are two service stations: one is a glovebox-like service and the other one is used for general maintenance where all parts of the ion source are being accessed very easy.

On top of the modul room there are cabinets with different parts for the PIG ion source service.

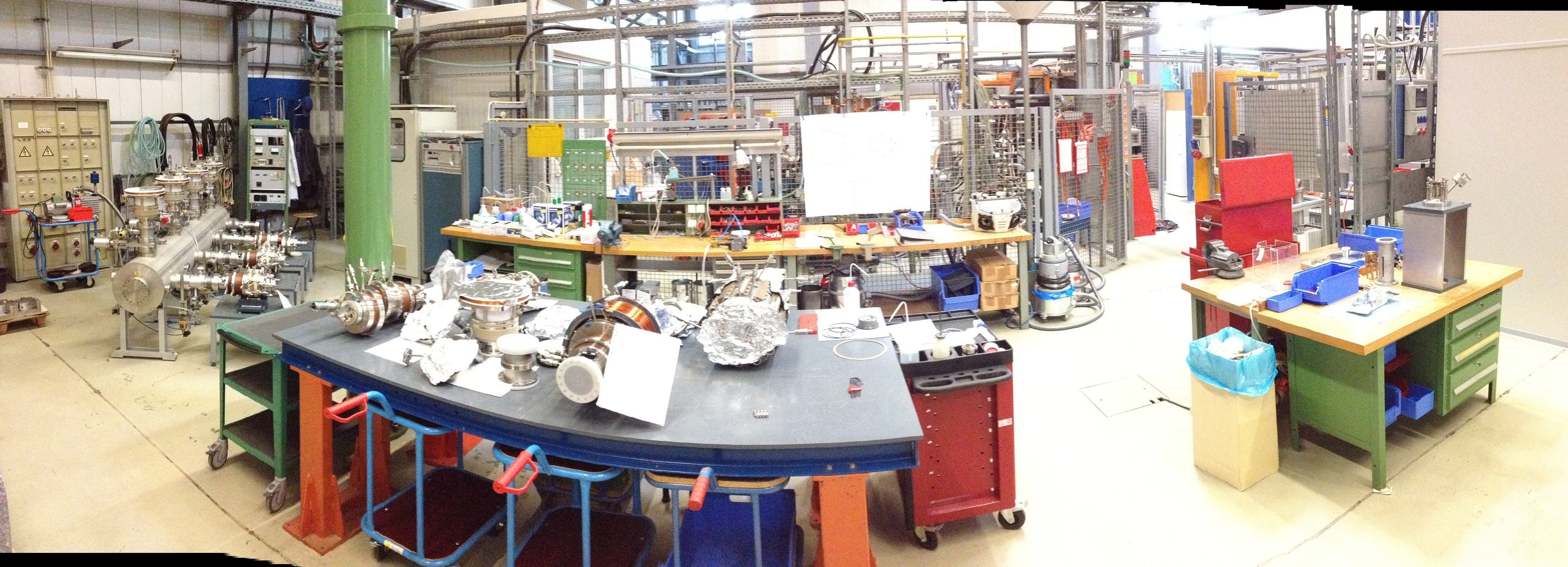

High current ion sources service area

Since various kinds of ion sources are operated, it is necessary to use an universal service area. In the high current service area the technicians are servicing all non-contaminated sources such as MEVVA, VARIS, CHORDIS and MUCIS.

ECRIS service Area

The ECRIS service area fulfills all specific requirements for the routine service of the ECR ion source and the low energy beam transport line.

It is equipped with a basic set of tools, two ultrasonic baths and a few machines needed for the maintenance of the ion source and its specific parts.

Attached to the service area is the preparation area where the plasma chambers are treated and prepared for the application in the next beam time.

ECRIS Evaporators – Service Area

While elements generated from gases can easily be transported into the plasma, materials in the solid state must be transformed into vapor. The method of thermal evaporation has been established and used at GSI for many years, because it resembles closely the operation with gases. A sophisticated technology using resistively heated ovens was developed. The effective thermal evaporation of metallic elements leads to long oven lifetime while the use of a load-lock system facilitates an easy maintenance for exchange or refilling of the oven. It is perfectly adapted to the needs of long beam runs at the accelerator.

Two types of ovens are in use for different temperature ranges. For most applications the standard oven (STO) is used covering a temperature range from 300°C up to 1600°C. For higher temperatures the HTO (High Temperature Oven) was developed operating at temperatures up to 2200°C. This workplace is dedicated to the service of the evaporator equipment including complete assembly and disassembly. A few parts of used ovens are replaced while most of the components can be cleaned.

Many experiments at GSI request beams of specific isotopes which require highly enriched isotope materials. Here the ECRIS is favorable due to its low material consumption and its high efficiency. For example the consumption of the very rare and expensive Calcium isotope 48Ca is in the range of 200 to 500 µg/. With a typical filling capacity of the oven of 300 mg a continuous operating time of 9 weeks can be achieved.