Successful start: Series production of SIS100 superconducting quadrupole units and quadrupole modules has begun

10.02.2022 |

In the large ring accelerator SIS100, the heart of the future accelerator center FAIR, various unique and custom-made magnets and entire magnet systems will ensure that the ion beam is precisely guided and focused. Series production of a crucial magnet group, the quadrupole modules, has recently started.

In addition to the superconducting dipole modules, the superconducting quadrupole modules are among the most important components of the SIS100. While there are only two different types of dipole modules, the series of quadrupole modules comprises eleven different types. Of these, two modules, for the areas of injection and extraction, have a particularly sophisticated mechanical design. Series production and cold testing of the 110 dipole modules were successfully completed in 2021, and has now begun for the quadrupole modules.

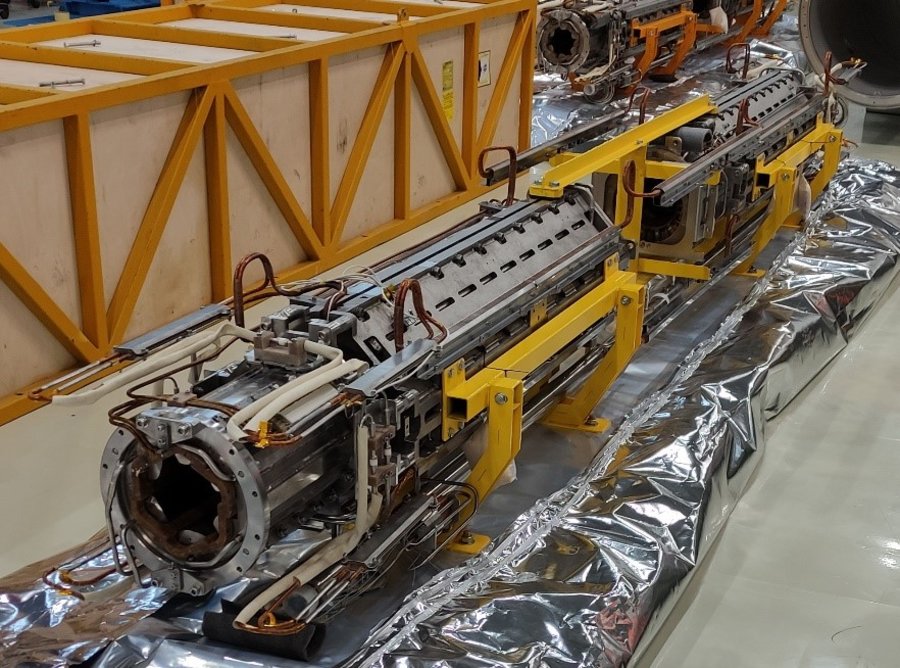

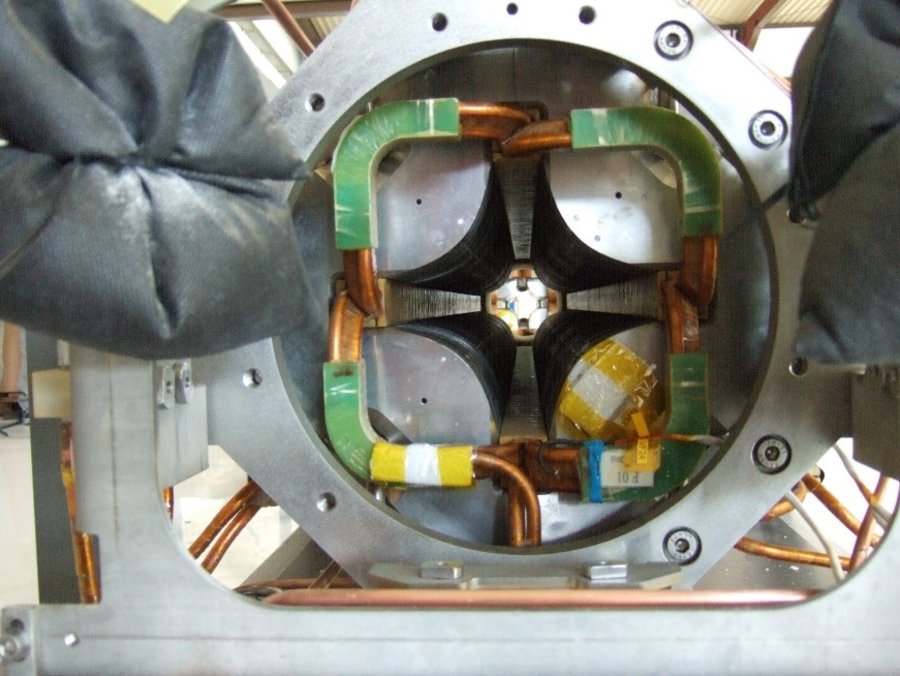

Essential components of the very complex quadrupole modules are the superconducting quadrupole units. Each module includes two quadrupole units. In addition to the quadrupole magnets in various configurations required for beam focusing, these also contain superconducting correction magnets, for example the "steerer" magnets required for path correction or sextupole magnets for correcting chromaticity, i.e. focusing differences caused by the energy distribution of the particles in the beam. These correction magnets are supplemented by additional superconducting magnets placed at the ends of the arcs.

All superconducting focusing and correction magnets are manufactured as a Russian Inkind contribution at the Joint Institute for Nuclear Research (JINR) in Dubna, Russia. The development of the magnet technology was carried out jointly by GSI and JINR during the project's preliminary phase. While the further developed Nuclotron cable is used in the quadrupole magnets as well as in the dipole magnets, a new, special superconducting cable with insulated strands had to be developed for the correction magnets. The design of the various quadrupole units, based on the joint development, is carried out by the GSI design office.

All quadrupole units are tested in Dubna in both warm and cold conditions. For the cold test at 4 Kelvin (which corresponds to 4 degrees Celsius above absolute zero at around -273 degrees), a cryogenic test facility comprising six test benches was previously set up under a collaboration agreement. This facility is used to test both the superconducting magnets of the future accelerator center FAIR being built at GSI in Darmstadt and the NICA accelerator facility currently being built at JINR in Dubna.

After extensive acceptance tests, all quadrupole units manufactured in Dubna will be shipped to Bilfinger Noell in Würzburg, which has been contracted to integrate the quadrupole modules. In addition to the quadrupole units from Dubna, GSI provides numerous other cryogenic components for integration, such as beam position monitors, ion catchers, and thin wall quadrupole chambers, among many others. The production of these components was previously ordered by GSI from various companies. The most important task here is the synchronization of all activities in time, a special challenge due to the technical complexity of the trades.

In parallel, negotiations were held with the Italian National Nuclear Physics Institute (INFN, Istituto Nazionale di Fisica Nucleare) for the use of the superconducting test facility in Salerno for the SIS100 project and a collaboration agreement was signed. The series of SIS100 quadrupole modules integrated at Bilfinger Noell will be tested at the test facility.

After successful implementation of the high quality standards and quality assurance standards at JINR, the successful start of series production at JINR and series integration at Bilfinger Noell was achieved. 26 quadrupole units could be manufactured and tested at JINR in 2021 and provided to Bilfinger Noell for integration. At the same time, the integration of the modules was parallelized at Bilfinger Noell. GSI will accompany the cold testing of the series modules in Salerno by testing about 20 integrated quadrupole modules at the "Series Test Facility" (STF) on the Darmstadt campus. (BP)